Direct Solid Wood Door Manufacturer in China

Factory Direct Pricing · Fast Lead Time · Reliable Quality & Service

✅ Competitive Factory Prices

✅ 20–30 Days Lead Time

✅ Strict Quality Control

✅ Trusted by Global Buyers

What is a solid wood composite door?

Sometimes we also call it a solid wood door.

Solid wood composite doors, as the name suggests, are made of various materials and are also a very popular type of wooden door nowadays. The main materials used are solid wood, MDF, plywood, and natural wood veneer.

The surface of the door leaf is made of MDF or plywood as the baseboard, with natural wood veneer applied on the surface. After high-temperature treatment, the natural wood veneer is firmly attached to the surface, and then it is painted in a dust-free paint booth.

The door frame material is made of MDF and wood, or plywood and wood. The surface treatment is the same as that of the door leaf: high-temperature natural wood veneer is applied, and then it is painted.

Tongyu Door Industry, as a professional manufacturer, has provided our high-quality wooden door products to more than 95 countries and regions and has received 100% positive feedback.

SOLID WOOD DOOR PANEL SRUCTURE

Surface material:

- Wood board + natural wood veneer + paint

- Plywood + natural wood veneer + paint

Internal Filling Material:

- Hollow particleboard / Solid particleboard / Solid wood / Honeycomb paper / MDF strips

Color:

- Solid color / Wood grain color /

Door leaf thickness:

- 35-50 mm (in most cases, users choose 45mm thick door leaves)

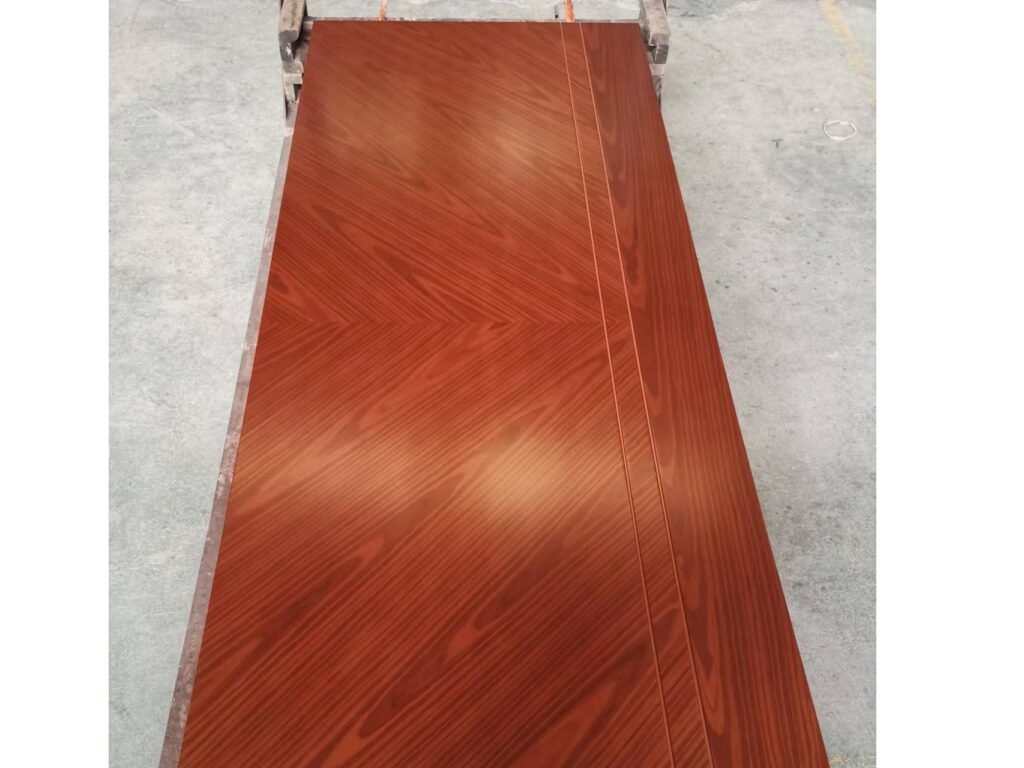

Due to the natural veneer used on the surface, the texture on the surface of the wooden door is the same as that of natural wood. And because of the variety of colors, she looks more beautiful!

Door Surface

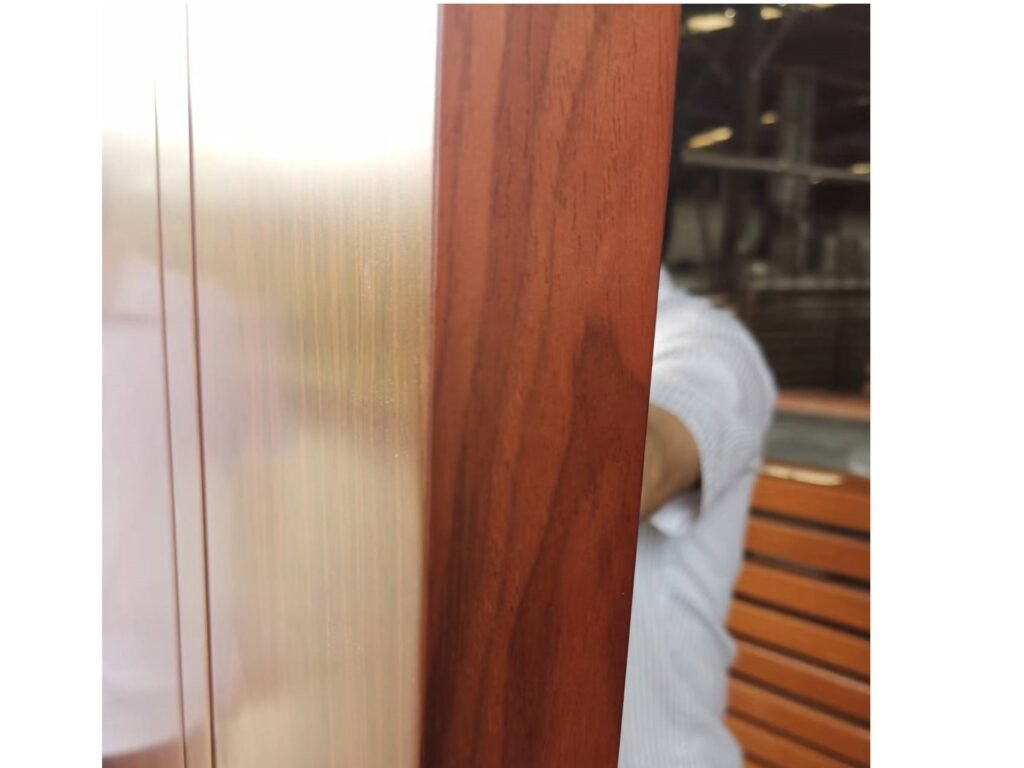

Door Edge Finish

Door surface finish color

SOLID WOOD DOOR FRAME SRUCTURE

The door frame of a solid wood composite door is made of the following materials:

- Wood: The main material of the door frame, usually made of Solid Pine Wood, solid fir wood or other hard wood.

- Medium-density fiberboard (MDF): A material made of wood fibers, used for the surface of the door frame to make it smoother.

- Veneer: Usually made of natural wood veneer or other decorative materials.

Door Frame

Frame lines

Frame set

The Advantages of Solid Wood Composite Door

Solid wood composite doors offer several advantages over traditional solid wood doors, making them a popular choice for both residential and commercial applications.

Stability

- Composed of multiple layers of wood bonded together with different orientations, which enhances dimensional stability and reduces the likelihood of warping, cracking, or twisting.

- More stable than doors made from single solid wood pieces, which are more susceptible to movement and deformation due to changes in temperature and humidity

Environmental Friendliness

- Efficient use of wood resources by utilizing smaller pieces and leftover materials from other wood products.

- Contributes to the conservation of forests by reducing the demand for large, single-piece timber

Sound Insulation

- Incorporates high-quality materials and fillers within the door’s structure.

- Effective in reducing noise levels and providing a more peaceful and quiet environment.

Durability

- Reinforced structure due to the bonding of multiple wood layers.

- Withstands wear and tear better than traditional solid wood doors, offering a longer lifespan.

Cost-effectiveness

- Manufacturing process requires less material and labor compared to solid wood doors

- More affordable option while still providing many of the same benefits and aesthetic appeal.

Design Versatility

- Ability to create a wide range of colors and textures through different wood combinations and surface treatments.

- Accommodates various design styles and preferences, from traditional to contemporary.

Overall, solid wood composite doors offer a compelling combination of performance, sustainability, and affordability, making them an excellent choice for door applications where stability, durability, and aesthetic appeal are important considerations.

High-Grade Materials

Tongyu solid wood composite painted door utilizes top-quality materials, employing a versatile combination to cater to various budget needs and usage scenarios. With a range of internal filling materials, it can fully meets the diverse requirements of different users.

High Quality MDF

The density boards we use are high-quality density boards, all of which have passed EPA, F☆☆☆☆, and CARB certifications. Just the right waterproof rate, not easy to break, better density.

Hollow Particleboard

The hollow particle boards we use are of high quality. It ensures a smooth surface with no obvious defects, high strength and durability, and is not easily deformed. It has good environmental protection and low formaldehyde emission.

Solid Particle board

Solid particleboard is basically the same as hollow particleboard, with a smooth and flat surface without obvious defects. High strength and durability, not easy to deform. It’s just that solid particle board has better nail-holding power.

High Quality Wood

All the wood is made of high-density fir, which is compounded to the E1 standard, ensuring the flatness of the wooden door, not easily deformed and cracked, and better nail holding power.

Plywood Board

Multilayer boards are a material often used on facades and door frames. The multilayer boards we use have better density, flatness, and lower formaldehyde emissions, ensuring that our wooden doors have more stable quality. Not easy to deform and more stable.

Wood Veneer

We cooperate with well-known brand veneer suppliers to ensure the quality of each veneer. Provide more veneer choices, the color of the veneer is more uniform, the texture is clearer and more beautiful, and the surface is smooth and flat.

Molded Door Veneer

Molded boards are also widely used in wooden doors. High-quality molded boards have better flatness, uniform color, clear texture, and are more cost-effective.

Water Base Paint

Water-based paint uses water as the diluent, while oil-based paint uses organic solvents as the diluent, so it is non-toxic and harmless, and has no pollution to human health and the environment. Low odor, fast drying and easy construction. Therefore, we choose to use high-quality water-based paint. The brands we use are the top three water-based paints in China.

Different Usage Scenarios

Solid wood composite paint doors are widely used in apartments, rooms, kitchens, bathrooms, wardrobes/closet, storage rooms, hospitals, villas, etc. due to their many advantages, such as: aesthetics, high cost performance, customizable styles, environmental protection, sound insulation, etc. . The following are some styles for your reference.

Pocket wood door

Louvered wood Door

Kitchen wood door

kitchen glass wood door

Interior room wood door

Hotel wood door

Hospital wood door

Entrance wood door

Closet wood door

Villa wood door

Bathroom wood door

Apartment wood door

Why Choose TongYu To your Partner?

As a manufacturer with more than 17 years of experience in wooden door manufacturing, TongYu can provide you with a full range of interior door manufacturing services. In the past 20 years of business development, we have continued to innovate and summarize, making Tongyu Door Industry’s products popular. Widely praised.

For a project or a need, you will enjoy wholehearted service from the moment you contact us. We provide free price calculations, style design, hardware recommendations, and professional suggestions for reference. We ensure that all inquiries will be answered within 24 hours, and the fastest will be answered within 2 minutes, and we have online inquiry services or telephone contact services. TongYu looks forward to your Contact.

FAQ

Are you a manufacturer or a trading company?

We are a professional wooden door manufacturer with over 18 years of production experience.

Our product range covers all types of wooden doors, including solid wooden doors, interior wood doors, primed wood doors, and more.

In 2025, we expanded our production capability by launching a new WPC door production line to better serve diversified market demands.

All products are manufactured in our own factory, ensuring factory-direct pricing without any middleman.

Where is your factory located? Can I visit?

Our manufacturing factory is located in Zhejiang, China.

We also operate an office in Shanghai, which is conveniently located near the international airport, offering easy access for client meetings and airport pickup service.

It takes approximately 3 hours by car from Shanghai to our production base.

What countries have you exported to?

We have served customers in more than 95 countries, including the USA, Canada, UK, Australia, Saudi Arabia, UAE, Chile, and European markets

What wood species do you offer?

Pine, Oak, Walnut, Teak, Ash, beech wood…

Are your doors suitable for exterior use?

This is a good question. Normally, wooden doors are designed for interior use only and are not suitable for outdoor installation. However, we use a newly developed type of paint. As long as the door is not directly exposed to rain, it can be used outdoors.

Can you customize size, design, and color?

For our wooden door products, we keep almost no pre-made stock. All doors are customized according to each customer’s specific requirements, including design/style, color, size, and hardware preparations such as lock bore holes and hinge cutouts.

How long is your production lead time?

Lead time:

20–25 days for standard models

35–40 days for fully customized orders

Can you match our samples or drawings?

Yes. We accept customization based on drawings, physical samples, or reference images.

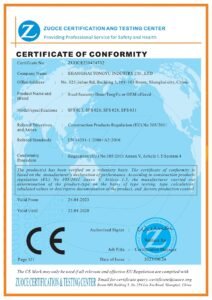

Certifications & Quality

Our products meet international standards and can provide

Our products meet international standards and can provide

ISO, SGS, CE, FSC, and test reports on request.

How do you control quality?

After the project is confirmed, we will first prepare detailed drawings for your approval. Once the drawings are approved, we will produce samples and color swatches for your confirmation of all details and colors. After everything is fully confirmed, we will begin mass production.

We have a highly professional QC team that conducts spot inspections on the production line in the workshop. If any defects are found, the items are immediately selected, clearly marked at the defect points, and sent back to the rework department for correction. This strict process ensures that all finished products fully meet our quality standards.

Are your doors moisture and warp resistant?

All raw materials are treated with moisture-proof protection. For door frames, we use moisture-resistant boards as the back panel to help prevent deformation. For oversized or extra-tall doors, we reinforce the door leaf with internal steel materials to enhance strength and prevent warping or deformation.

How are doors packed for shipping?

Our packaging methods are mainly divided into three categories:

Separate packing of door leaf and frame

The door leaf and frame are packed separately. Pearl cotton or foam boards are placed on the surfaces to protect the painted finish. All four corners of the door leaf are protected with foam corner guards to prevent impact damage. An outer carton is used, with full product information clearly marked. This packing method provides excellent protection for both the door and frame and also maximizes container loading efficiency.Separate pallet packing of door leaf and frame

The door leaf and frame are still packed separately, but each is secured on individual pallets. This method makes unloading much easier and more convenient for customers upon arrival.Pre-hung (pre-assembled) packing

The door leaf and frame are pre-assembled into a complete unit first, then secured with wooden battens and packed on pallets. This method is ideal for projects that require pre-hung doors ready for installation.

What is the minimum order quantity (MOQ)?

There is no strict MOQ requirement for our wooden door products. Normally, orders of 20 sets or more are acceptable.

What is the minimum order quantity (MOQ)?

There is no strict MOQ requirement for our wooden door products. Normally, orders of 20 sets or more are acceptable.

What payment terms do you accept?

T/T and LC